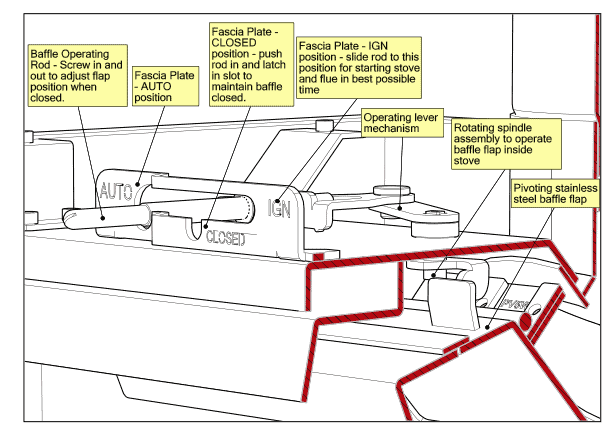

PureVision range, including the Classic versions may be fitted with an internal stainless steel active baffle assembly which fulfils a number of functions depending upon the setting mode as follows:

a) IGN Position: Direct access of ignition heat into flue-way to start up cold, inactive flues in a quicker and more user-friendly way.

b) Auto Position: Opening of the flue way when refuelling to enhance the fume removal capacity of the stove when the door is open.

c) Closed (Manual) Position: A manual override position to retain the baffle in the permanently closed position when its assistance is not required.

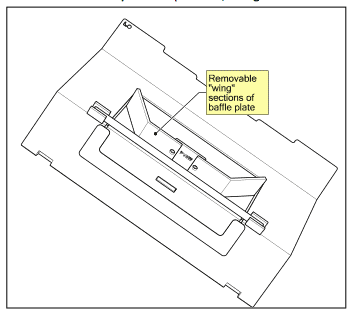

d) In the case of a low draught flue where it has been improved as far as possible by conventional means (e.g. flow enhancing terminal, increasing height and diameter and reducing bend severity and number where possible) the removable sections of the baffle can ease gas flow to enable safe use of the stove where otherwise it may not be possible to continue to use a wood burning stove (see 4 below).