What are the differences between a conventional and a balanced flue?

A flue is a pipe, duct, or simply an opening in a chimney. It is designed to transport gases from a fire. In the past, a flue literally meant the chimney itself. However, over time, this has changed somewhat. A flue is not just used for space heater applications (fires) but in many other applications too, which range from furnaces to boilers. For the purpose of this article, we will just be looking at the difference between a conventional and balanced flue for fires.

Conventional Flues – Fires with conventional flues rely on the natural circulation of air in a room to remove gases from combustion. They work with traditional open fires and glass-fronted fires. The air which is needed for combustion is supplied from the room the appliance is installed in.

Ventilation points are needed at the front of a fire that has a conventional flue, so it can essentially “breathe” and assist in the convection of the radiant heat from the fire.

Conventional flues are not quite as efficient as balanced flues as they draw in air from the (warm) room. This air, which has already been or is being heated by the fire, will be taken away to aid in the combustion process. Although not as efficient as balanced flues, this is a perfectly natural process that comes from combustion and the requirement for the use of air.

Below is a Paragon CF (Conventional flue) Gas Stove

Balanced Flues – Balanced flue fires are more efficient than their conventional flue counterparts as the fires are totally sealed from the room. Essentially, there is no drawing of air from the room, which impacts efficiency.

With a balanced flue, the air is taken into the fire via a twin outside pipe (not from the room) mounted on an outside wall towards the rear of the fire. The removal of combustion gases exits from the second vent in the wall to create an ultra-high-efficiency heating method.

A balanced flue is an ideal solution when you don’t have a conventional chimney. These tend to be more common in newer build properties.

Below is a Focus RS Balanced Flue fire

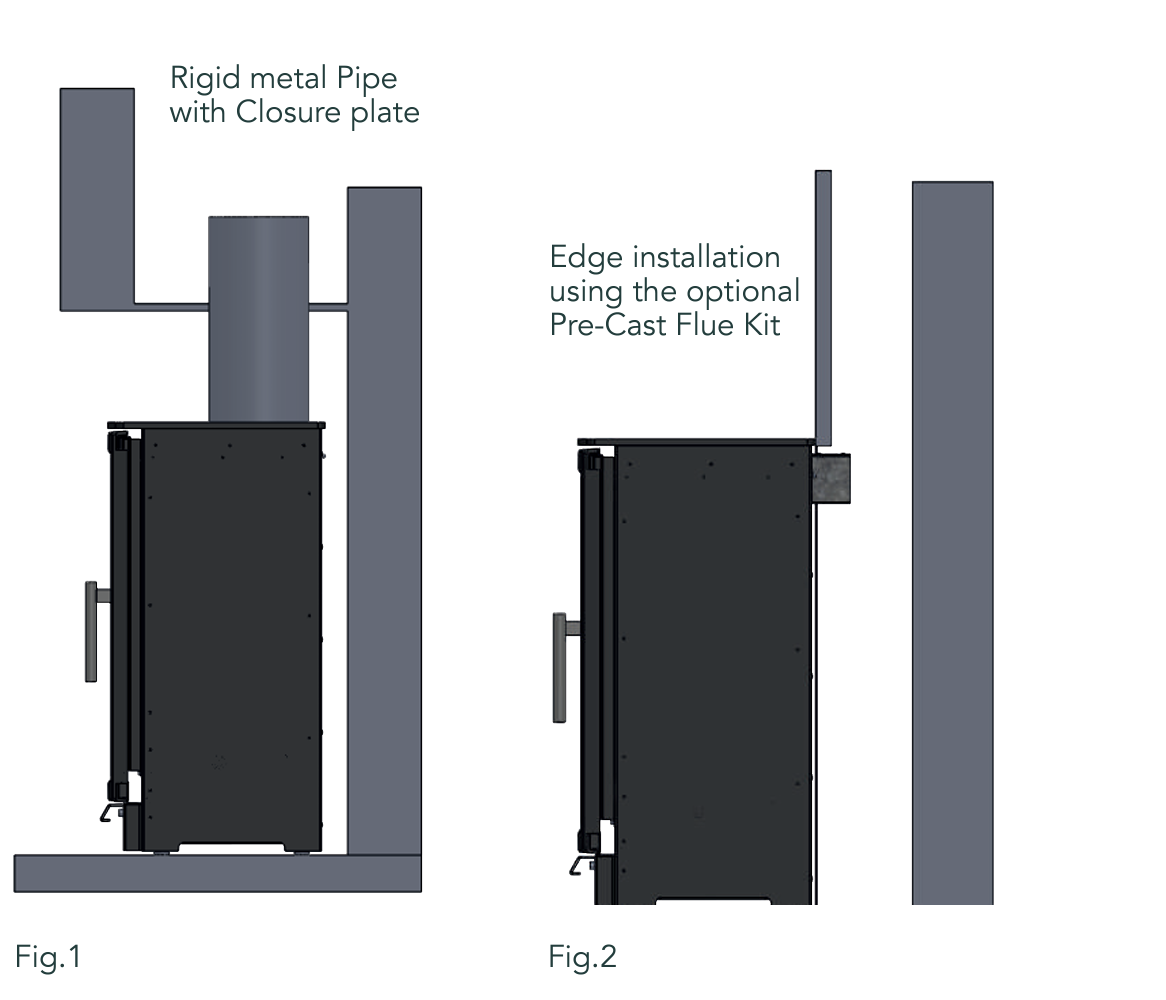

Flue Options – Paragon Edge case study

In the Charlton & Jenrick range, there are flue options designed to fit your needs. The Paragon Edge CF and Edge 3S CF, for example, can be installed as a top outlet stove (Fig.1 below). The optional pre-cast flue kit for the Paragon Edge CF and Edge 3S CF Stoves will allow installation into properties without a conventional brick or clay liner flue system. This allows installation onto a flat wall via a pre-cast flue system within the cavity structure of the property (Fig.2 below):

And for balanced flues……the two options

Option 1. Balanced Flue – with a rear vent – For rooms which do not have a flue, the Paragon Edge BF and Edge 3S BF Stoves may well be an alternative. The Paragon Edge BF and Edge 3S BF Stoves can be fitted using two different balanced flue systems. A snorkel system allows direct ducting of the exhaust products via a rear exit connect on an external facing wall. The Snorkel kit comes with a standard 600mm flue length, which is cut to suit the cavity wall depth.

Option 2. Balanced Flue – top vent up & out – The other alternative is the up and out balanced flue kit from Paragon. This allows up to a 3 metre vertical run off the top of the appliance and will also allow a 5 metre horizontal flue in total. The up and out kit provided as standard allows for a vertical run of 800mm plus a 90 degree elbow with terminal which is cut to suit the cavity wall depth. Further components are available to order.

Whether you choose a conventional or balanced flue, you can be confident that if you buy a fire from us, you are buying a high-quality, high-efficiency fire. We offer fires that work with both conventional and balanced flues.