How is Wood Kiln Dried?

You have two options when it comes to having the correct moisture content wood for your stove. Option one is to season it yourself, which can take one to two years, or buy from a retailer who, like you, has seasoned it, again, which can take one to two years.

The second option is to buy kiln-dried wood. Kiln drying logs are a much quicker way to get firewood to the correct moisture level for burning – around 20%. Too high moisture and you will be creating excessive smoke and pollution with a poor heat output, too low moisture content and wood will burn too fast.

Benefits of Kiln Drying

Reduced Moisture Content: Achieves a specific moisture level.

Pest Control: Kills insects and larvae present in the wood.

Enhanced Durability: Prepares wood for long-term use without excessive movement or degradation.

Improved Stability: Minimises shrinkage, warping, and cracking.

Here is how wood is kiln-dried:

Preparation of the Wood:

Logs are cut into lumber of desired sizes. The wood may be air-dried initially to reduce moisture content before entering the kiln, depending on the desired final moisture level, which is usually around 20%.

Loading the kiln:

The wood is stacked inside the kiln with spacers (called stickers) placed between layers. This arrangement allows air to circulate around each piece of wood.

Controlled Environment in the Kiln:

Kilns are enclosed chambers where temperature, humidity, and air circulation are carefully controlled. Types of kilns include:

Conventional Kilns: Use heated air.

Dehumidification Kilns: Recycle heated air to remove moisture.

Vacuum Kilns: Remove water vapour at lower temperatures using a vacuum.

Solar Kilns: Use solar energy for heating.

Drying Phases:

Initial Heating: The kiln heats the wood to raise the internal temperature and start evaporating moisture.

Moisture Removal: As the wood heats up, water migrates from the inner cells to the surface, where it evaporates.

Controlled Humidity: Relative humidity is managed to prevent drying too quickly, which can cause defects like cracking or warping.

Equalization: Once the target moisture level is reached, the kiln adjusts conditions to even out the moisture throughout the wood.

Monitoring:

Moisture content is regularly measured using moisture meters or sample boards removed from the kiln. Temperatures and humidity levels are adjusted as needed to ensure uniform drying.

Final Conditioning:

To relieve drying stresses and stabilize the wood, the kiln may enter a conditioning phase where moisture is slightly reintroduced to balance the drying process.

Seasoned or kiln-dried – do you know the difference?

The main difference between seasoned wood and kiln-dried wood is actually very little. Technically, well-seasoned logs should be dried to around 20% moisture content. However, although some sellers may try to tell you the wood is well seasoned, this sadly is not always the case. You will know if “well-seasoned” firewood is not that well-seasoned if it struggles to burn and leaves a blackened window on your stove.

Luckily, since 1st May 2021, the government has been phasing out the sale of wet wood sold in small volumes (under 2m3) in England. Wood products sold in volumes over 2m3 do not need to be certified as Ready to Burn, but they must be sold with advice on drying and an explanation of the issues of burning wet wood. Always look for the Ready to Burn logo on small volumes of logs.

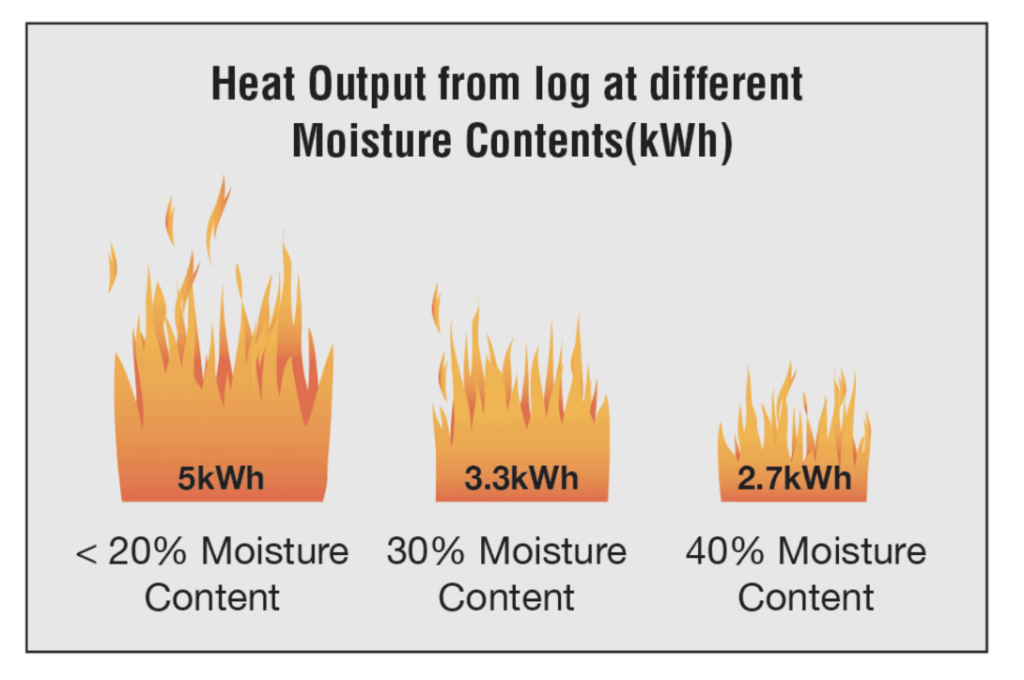

Burning correctly seasoned wood, whether that be by traditional seasoning or by kiln, has significant benefits. Below, you will see the heat output which a log provides based on its moisture level.